Membrane switches are everywhere, but not everyone is familiar with them. So, What is a Membrane Switch? A membrane switch is a momentary electrical switch that is used to turn a circuit on and off. It consists of several layers of flexible materials with printed circuits. These switches are widely used in various applications such as industrial controls, medical devices, and consumer electronics. Importance of Membrane Switches can be gauged from the fact that they provide a reliable and cost-effective solution for enabling user-interface with electronic devices.

Types of Panel Materials:

The two most commonly used materials for membrane switch panels are polyester and polycarbonate. Both of these materials have their own set of characteristics that make them suitable for specific applications.

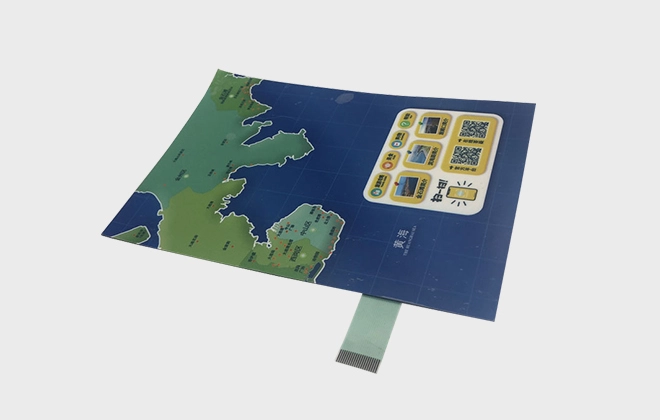

Membrane Switch are incredibly user-friendly. They can be designed to incorporate graphic overlays, making them intuitive to use even for first-time users.

These switches are known for their reliability. They can withstand a high number of cycles without showing signs of wear and tear.

Membrane Switch are resistant to harsh environments, including extreme temperatures, moisture, and chemicals.

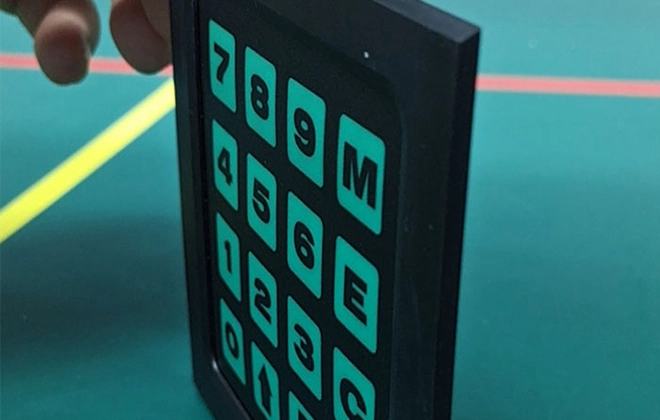

They can be customized to fit a wide range of applications, making them suitable for various industries.

Membrane switches are used in a wide range of electronic devices and applications. Here are some common uses of membrane switches:

Consumer Electronics

Industrial Control Panels

Medical Equipment

Automotive

Aerospace and Aviation

ATM and Point-of-Sale (POS) Systems

Military and Defense

Appliance Control Panels

Security Systems

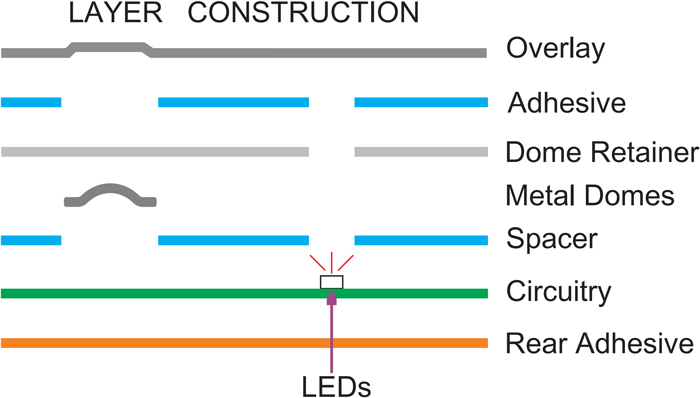

Niceone-tech can customize products that are perfect and best suited to customer requirements according to customer needs. In order to let you know how the best and most suitable membrane switch is produced, we must talk about its structure:

Overlay-Polyester is usually the first choice for membrane switch panel materials, because its life will be a little longer than Polycarbonate. If it is simply a panel instead of a membrane switch, Lexan and Polyester are also good choices. Overlay is the most intuitive form of human-machine interface. Niceone-tech will screen print or digital print on the back of the material, and they can also be used in combination. Special requirements such as mirror silver effect are also feasible.

Working Voltage | ≤50V(DC) | Working Current | ≤100mA |

Contact Resistance | 0.5~10Ω | Insulation Resistance | ≥100MΩ(100V/DC) |

Basic Withstand voltage | 2kV(DC) | Loop resistance | ≤50Ω, ≤150Ω, ≤350Ω |

Button Lifetime | >0.5-1.0 million times | Button Stroke | 0.1-1.5mm |

Button Feed BackTime | ≤6ms | Tail Folding | No limit |

Working Temperature | -20℃~+70℃ | Stock Environment | -40℃~+85℃, Sealed |

Many working environments and machines will be used in low light or dark conditions. At this time, the customer asked us if we could solve this problem. At this time we will recommend the use of membrane switches with internal lighting. Choose EL film as the light guide plate, Fiber Optics, and the newer Light guide film (LGF) structure. Niceone-tech recommends LGF, which uses side LEDs and light guide panels to make the product have lower loss and longer life relative to EL membrane switch. Also available in different colors.

The thickness of the LGF membrane switch provided by Niceone-tech can even be 0.8mm. The brightness of buttons and logos is not only uniform and long-lasting but more importantly, we can also make them illuminate each button individually. Sometimes you can also use two-color or RGB three-color lights to enter

One step makes the product more beautiful.

*If the customer wants the product to be more novel and beautiful, then we can sometimes use Epoxy in combination with the keys. Makes it an Epoxy LGF membrane switch

If you are interested in Backlit Membrane Switch, please feel free to contact Niceone-tech, we will send samples as soon as possible.

There are three other types of illuminating membrane switches below.

Fiber optic membrane switches are also a good choice for backlighting. The optical fiber material is very thin and can be used as a fixed layer of the membrane switch. At the same time, tactile feedback is better without adding a touch point. Life expectancy is up to 50,000 to 100,000 hours. The main light source is from LEDs

Through the optical fiber transmission in the membrane switch needs to light up. And can be larger than the surface-mounted LED backlight area. Click Fiber Optics membrane switch for more information.

EL backlight is driven by high frequency and low power. EL is very thin, it is a substitute for traditional lighting technology, and is widely used in various electronic accessories. The life of EL backlight products mainly depends on the driving voltage, frequency, temperature and humidity. But most EL membrane switches can reach a life of 4000 hours or more. The brightness of the EL membrane backlit switch will attenuate linearly from the initial power-on. This is also an unavoidable disadvantage relative to other backlight membrane switch panels.

The EL backlit membrane switch provided by Niceone-tech will not cause heat, electricity and EMI problems. Mainly EL is more often a "cold" lighting medium.

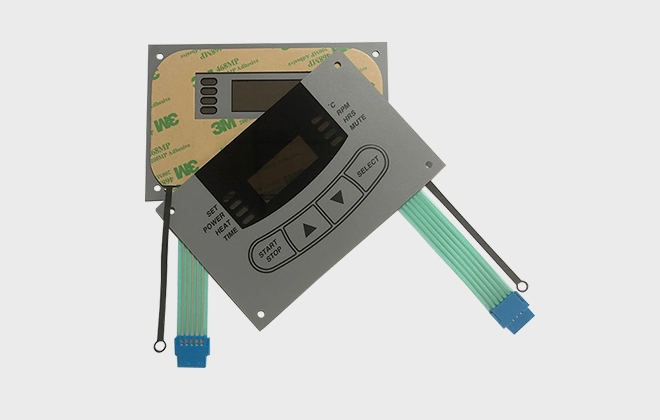

A common Light Emitting Diodes membrane switch (LED membrane switch) with relatively low cost. Since this technology membrane switch cannot meet the lighting of a large area, it is mostly used for indication purposes. It is a relatively old technology. But the service life is long and deep customers love it.

Common design:

*Graphic overlays digitally and/or screen printed on the backside. The effect can be customized according to your requirements including glass, metal, wood, and stone. If the panel is in a more severe environment, we can even use hardened glass and stainless steel as the panel material. It is very important to choose Overlay printing according to requirements.

*The window needs raw materials to be transparent, frosted, transparent or colored. The window of the membrane switch is different, and the choice of materials is also very different. When the window is large, and it is required to clearly see the bottom LCD or touch screen. EBG series is a good choice, the material is scratch resistant. If it is just a panel, then PC or Lexan overlay is also feasible

*Selective textures and UV hard-coat surface finishes

*Tactile or non tactile, snap dome or non snap dome.

*Pillow rim-embossed membrane switch panels

*Optically clear adhesive(OCA),Liquid Optically Clear Adhesive,Air Gap

*EMI/RFI shielding

*Rigid support backers such as aluminum and FR4 with PEM mounting fasteners

*Standard connectors such as CJT, Nicomatic and molex, etc.

Medical Equipment and laboratories are the major markets. Niceone-tech provides customized membrane switches with complex requirements for many European and American manufacturers. In the medical environment, based on the standard membrane keypad, the materials sometimes have antibacterial effects and easy cleaning characteristics. At the same time Niceone-tech applies backlit and glue technology to the membrane switch. It can even be produced using digital printing.

Industrial Controls Because industrial equipment is more demanding moisture resistance and UV resistance, so the product's waterproof requirements and UV resistance performance requirements are relatively high. The choice of materials can refer to the membrane switch design guide, I believe that the materials compiled by Niceone-tech can help you.

Health & Fitness Equipment Because it is often corroded by sweat, salt and moisture, the material must be resistant to corrosion. Membrane switches are often used in treadmills. Using membrane switches to optimize performance and control is very important for fitness personnel.

Contact Niceone-tech today, or visit our Product Gallery for high-performance inventory and customized membrane switches for your unique applications. If you have any questions, please contact info@niceone-tech.com.

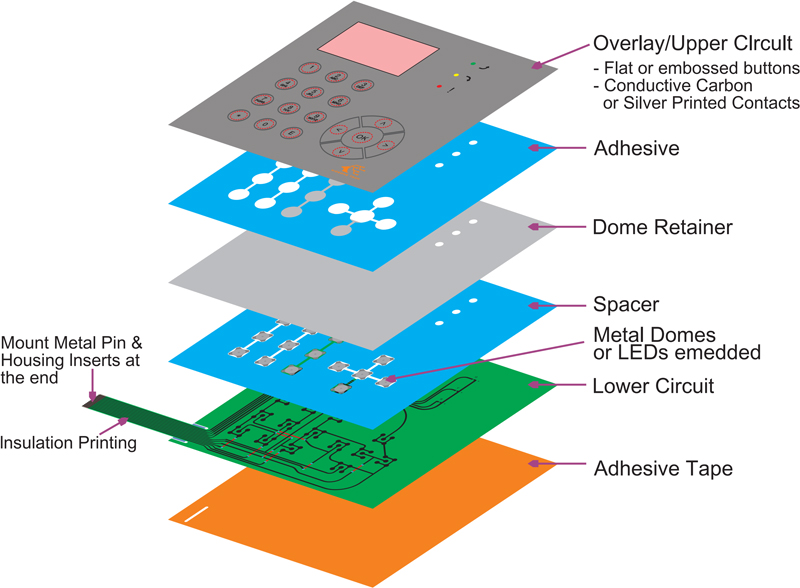

Membrane switches are made of several layers of materials, including a graphic overlay, top circuit layer, spacer layer, bottom circuit layer, and rear adhesive layer.

When you press a key on the membrane switch, it flexes and makes contact with the bottom circuit layer, completing the circuit and sending a signal to the device.

Membrane switches are durable, resistant to contaminants, and easy to clean.

Membrane switches have some limitations in terms of design and are sensitive to extreme temperatures and UV radiation.

Membrane switches are used in various applications, including consumer electronics, industrial equipment, and medical devices.

Niceone-tech customized membrane switches for different customers are widely used in various industries, empowering exceptional product design for other man-machine interface solutions.

Membrane switch constantly updates and upgrade their technology, and their durability is gradually improved. Because of its superior performance and affordable price. As a reliable human-machine interface, it is increasingly favoured by home, office and industrial applications.

Niceone-tech strictly customizes products in accordance with ISO9001-2015 and invests a lot of money every year to develop the technology of the membrane switch to improve the added value of products such as performance, life and function. Our membrane switches are exported in large quantities to European and American countries with stable quality and affordable prices. Niceone-tech understands the standards of European and American countries, so the products are always able to meet and exceed customer expectations.